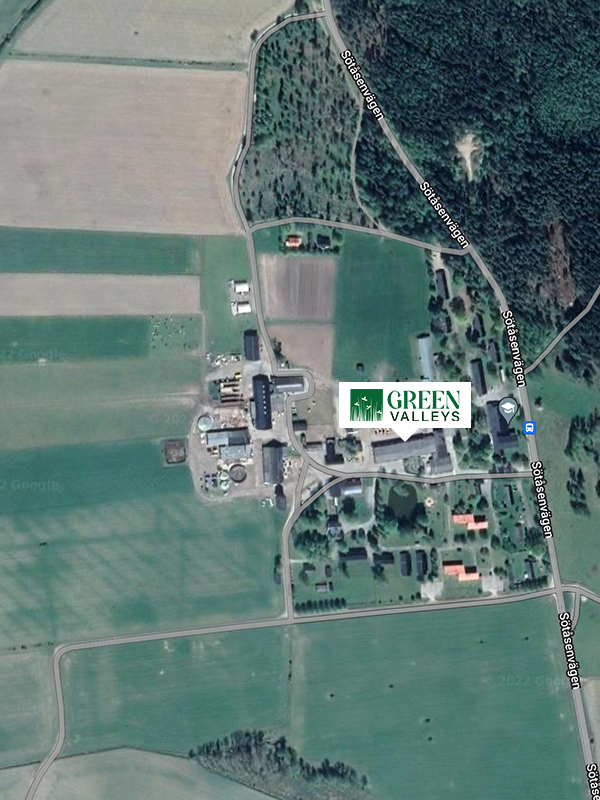

Facility for green biorefining outside of Töreboda

During the spring of 2020, the demonstration facility for green biorefining was established at the Sötåsen School of Agriculture outside Töreboda. The school also has a biogas plant for farm-based use that was used in the project. The biorefinery at Sötåsen is smaller than the facility in Foulum and has a capacity of about 2-4 tons of grass per hour.

Biorefining of silage

The facility consists of an unloading table equipped with a roller/reflector that distributes the chopped grass evenly and avoids the risk of clumping. The grass is then transported to a double-screw screw press, which compresses the grass under high pressure to produce a fiber-rich press cake and a protein-rich press juice. The press cake is further transported out of the facility via a conveyor belt. The pressed juice is collected in a smaller vessel and then pumped on to a larger buffer tank with agitation where it is kept chilled.

At the plant at Sötåsen, a silage has mainly been pressed, in order to be able to run the plant all year round. The fiber-rich press cake has been used within the project as feeding for dairy cows and heifers, while the protein-rich press juice has been used as a supplement for wet feeding for growing pigs and sows.

Protein extraction since summer 2021

The biorefinery at Sötåsen also has a step for protein extraction established since summer 2021. By pressing fresh grass in the facility, the fresh press juice that is formed can be heated for protein extraction. The liquid is heated in two stages, first through a heat exchanger to approx. 65 degrees and then via a steam injector which heats the liquid further to approx. 80-85 degrees. The protein coagulates and precipitates and can be separated through a decanter centrifuge integrated into the biorefinery. In addition to a protein-rich pasta, a residual juice/brown juice is also formed that can be used in the biogas plant at the school.