Conventional natural sources of textile, such as cotton, require large amounts of land, water, and pesticides. At the same time, the demand for textiles is increasing worldwide1. Thus, a sustainable alternative is needed – such as grass.

Image: One sample is 100% grass and the other is 50/50% grass/conventional wood pulp.

Photo: J Ronkainen

Cellulose is a natural material found in all plants, together with lignin and hemicellulose, it forms three main components that comprise the majority of all plants. Cellulose forms the primary structure of the plant cell, with the hemicellulose wrapping between the cellulose and connecting the cellulose molecules.

Lignin provides strength and rigidity to the plant cell.

Cellulose can be purified from various plants and used for textile production through different processes to form textile such as Lyocell and Viscose. However, these methods are energy intensive and use harsh chemicals.

A more environmentally friendly purification method is needed to lower the environmental footprint of the textile industry.

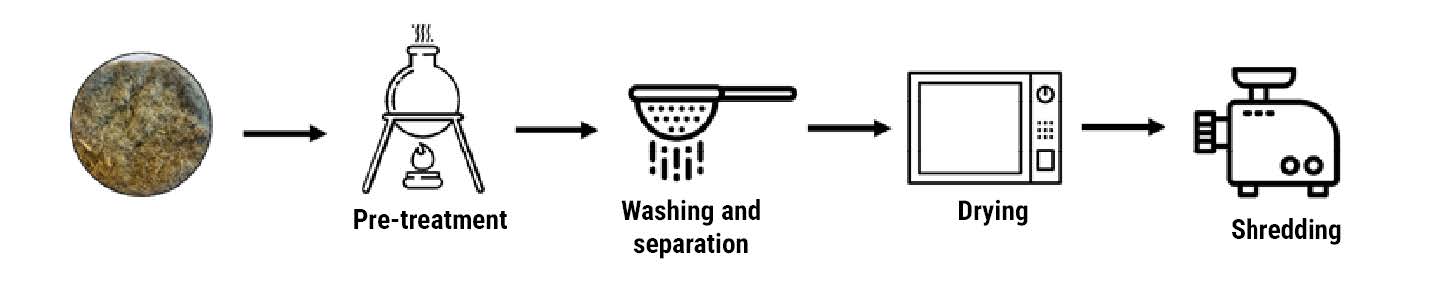

The green biorefinery at AU Viborg extracts protein from grass. From this process there are two residual products, brown juice and press cake fraction, both of which are currently used for biogas. The press cake fraction from the biorefinery can be purified into a cellulose-rich dissolving pulp, which can be dissolved and spun into textile filaments. Using a residual product from the biorefinery as a raw material for textile production, adds another high-value product to the value chain in utilising the full potential of biomass.

The hemicellulose and lignin are dissolved and removed from the grass pulp through the pre-treatments, leaving a concentrated cellulose dissolving pulp. The different pre-treatment methods involve heating the pulp under pressure, first with a weak acid and then base.

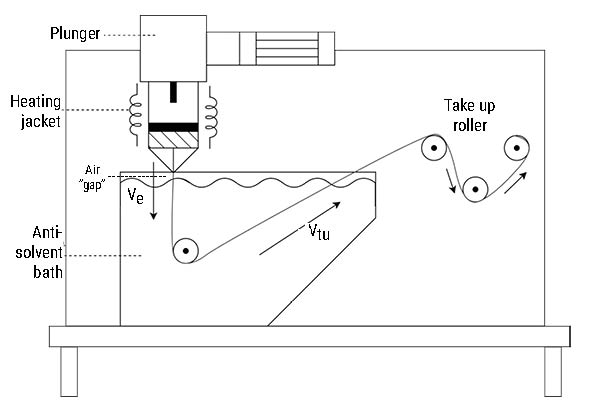

By using liquid salts, called ionic liquids, the cellulose can be dissolved. This happens because the ionic liquid interacts with the cellulose chains, making the otherwise insoluble cellulose soluble.

The cellulose solution, also called “dope”, is very viscous and stringy. When the dope is exposed to an anti-solvent, such as water, the cellulose will become solid. It is then possible to manipulate the dope into a desired shape, such as a film or filament, and precipitate the cellulose, which will remain in this form. These properties make it possible to spin the solution and form threads for textile production.

The spinning of the dope involves pressing the dope through small holes, called a spinneret, with or without air gap between the spinneret and the water.

The shaped filaments are then pulled through the water and onto motorised rollers called “take up rollers”. The stretching of the fibers increases the strength. After spinning, the filaments are placed in a water bath to remove all ionic liquid.

From grassland biomasses to textile product

1. Press cake, 2. Acid pre-treated biomass, 3. Dissolving pulp, 4. Spin dope, 5. Regenerated cellulose yarn, 6. Knitted textile

Photo: J Ronkainen

Want to know more?

If you want to know more or have questions you’ll find the contact people for this work package down below.